Nanocomp Coatings for Aluminium Permanent Moulds

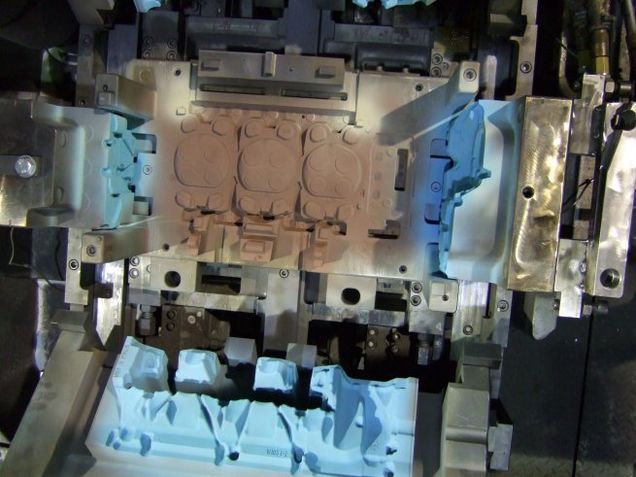

CeraNovis GmbH provides high performance base coatings and a nano-ceramic top coating for aluminium permanent mould casting. The service time of coating is increased by 200 – 500% compared to conventional coatings. In most cases, customers can use moulds an entire week without shot blast intervention. The coatings are used for wheels production, cylinder head and engine production and general use.

Our 2022 innovation - the fully nanoceramic RIMBOP provides excellent casting quality and highly improved service time in wheel casting and other LPDC processes.

Nanocomp coatings are saving maintenance cost and improve productivity as well as parts quality.